Oil Turbine Flow Meter

- Caliber:DN4-DN200

- Accuracy:±0.5%, ±1%

- Output:40-20mA

- Medium temperature:-20~80°C

Introduction:

Turbine gas flow meter consists of turbine flow sensor and display instrument and it is made by us using foreign state-of-the-art technologies, which is an ideal gauge for measuring of liquid flow. The flow meter is characterized by simple structure, high precision and easy installation and repair. The product may be used in a wide range of industries, including oil industry, chemical industry, metallurgy, water supply, paper-making, environment protection and food industry.Features:

♦ Have good performance on antiy-seismic and surgin flow

♦ High accuracy,±0.5% of rate or ±1.0% of rate

♦ Adopte micro-power technology,power consumption is low,it could be powered by battery

♦ Small loss of pressure,fine repeat

♦ Simple and firm structure, easy for installation and dismantling.

♦ Wide range of measuring with very lower flow velocity limit.

♦ High resistance to electromagnetic interference and vibration

♦ Turbine flow meter adopt new type sensor with lower pressure loss,starting flow is small-corrosion with long term work life

♦ The sensor is with hard alloy bearing thrust type, which may guarantee the precision and improve the wear resistance performance as well.

.jpg)

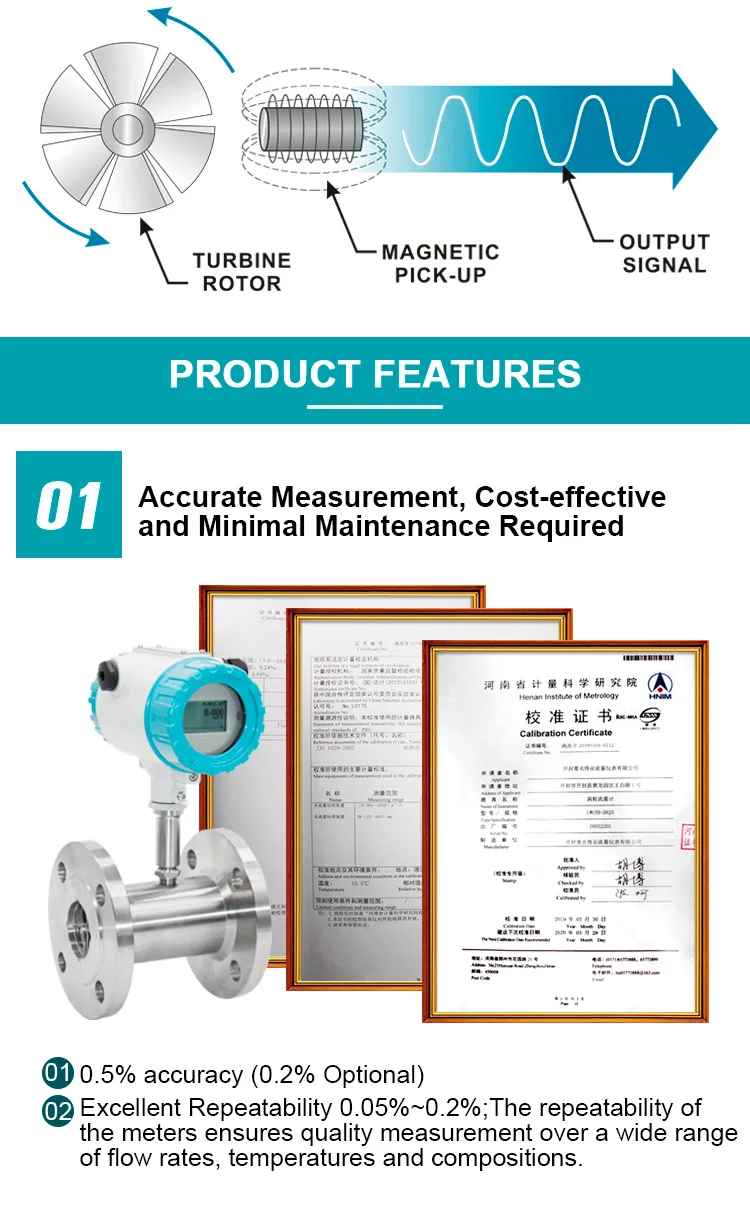

A turbine flow meter is used for volumetric total flow and/or flow rate measurement and has a relatively simple working principle.

As fluid flows through the turbine meter, it impinges upon turbine blades that are free to rotate about an axis along the center line of the turbine housing.

The angular (rotational) velocity of the turbine rotor is directly proportional to the fluid velocity flowing through the turbine.

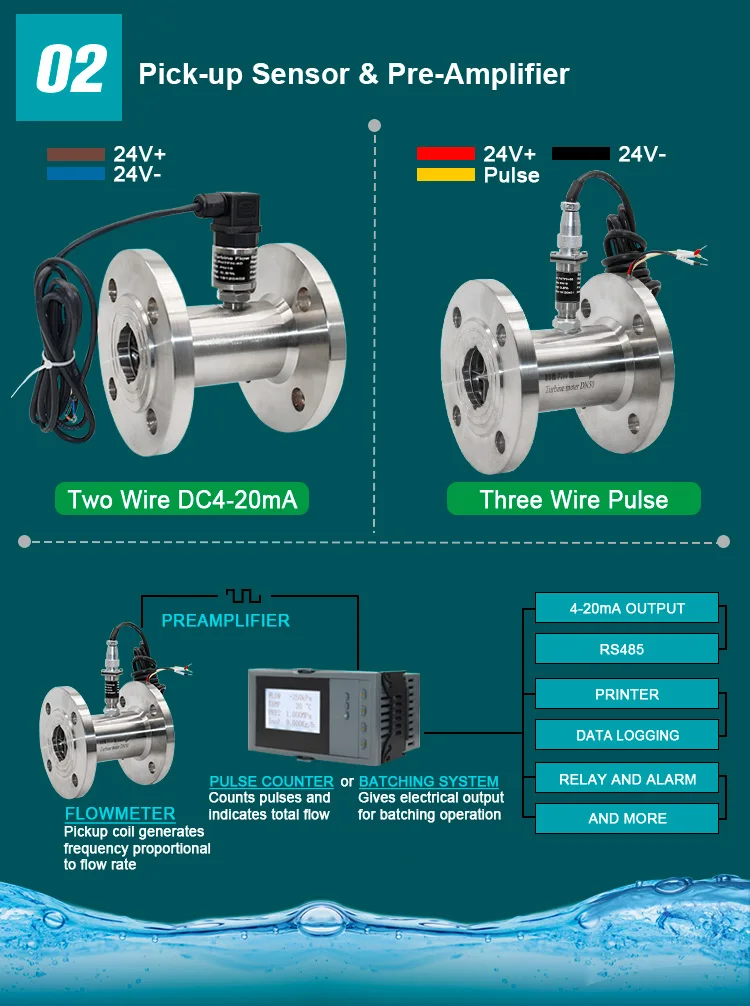

The resulting output is taken by an electrical pickoff(s) mounted on the flow meter body.

Technical Performance Parameters

| Size & Process Connection |

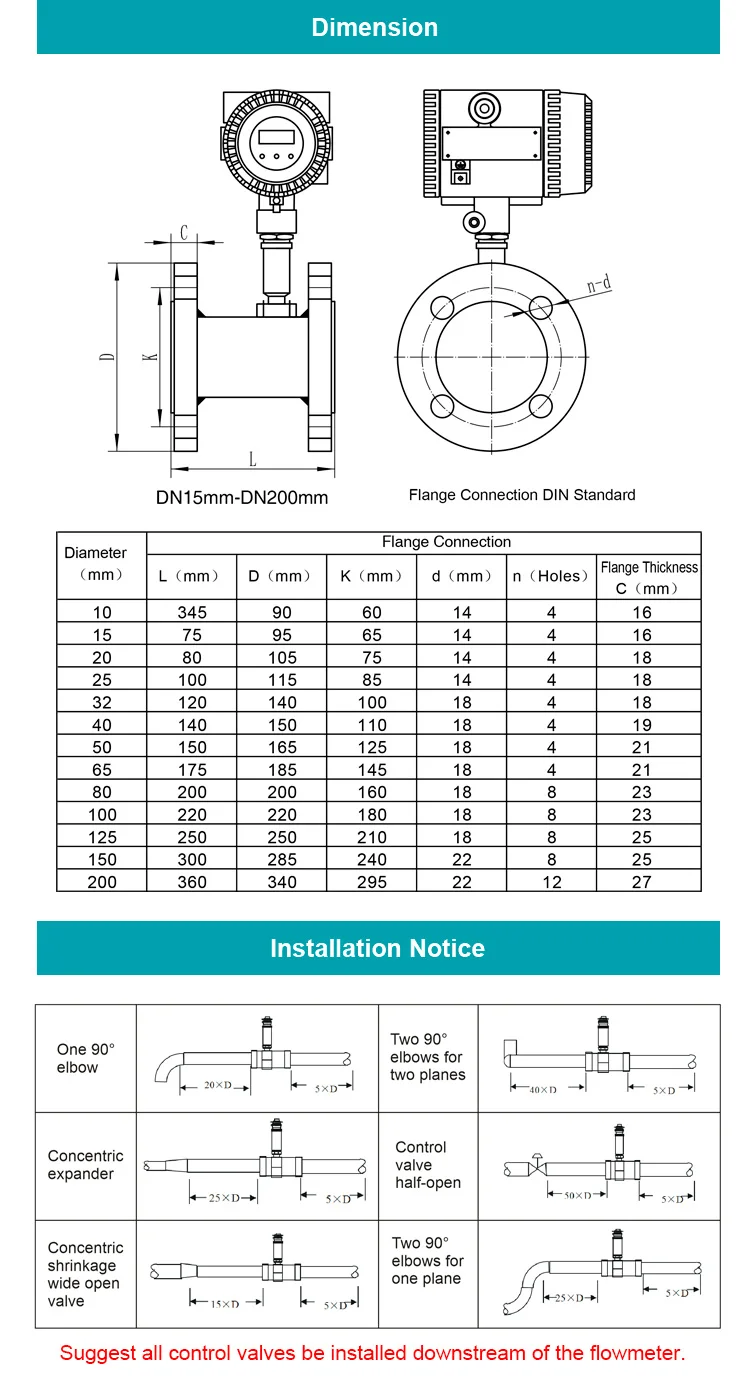

Thread connection:DN4,6,10,15,20,32,40,50,65,80,100 Flange connection:DN15,20,32,40,50,65,80,100,125,200 Clamp connection:DN4,6,10,15,20,32,40,50,65,80,100 |

| Accuracy | ±0.5%, ±0.2% Optional |

| Sensor Material | SS304, SS316L Optional |

| Ambient Conditions |

Medium temperature:-20℃~+150℃ Atmospheric pressure:86Kpa~106Kpa Ambient temperature:-20℃~+60℃ Relative humidity:5%~90% |

| Signal Output |

Pulse, 4-20mA, Alarm(optional) |

| Digital Communication | RS485, MODBUS; HART |

| Power Supply |

24V DC/3.6V Lithium Battery |

| Cable Entry | M20*1.5; 1/2"NPT |

| Explosion-proof class | Ex d IIC T6 Gb |

| Protection class | IP65; IP67 Optional |

Flow Range

|

Diameter (mm) |

Standard Range (m3/h) |

Extended Range (m3/h) |

Connection Standard(Optional) |

Standard Pressure (Mpa) |

Customized Pressure Rating(Mpa) |

| DN4 | 0.04~0.25 | 0.04~0.4 | Thread | 6.3 | 12,16,25...42 |

| DN6 | 0.1~0.6 | 0.06~0.6 | Thread | 6.3 | 12,16,25...42 |

| DN10 | 0.2~1.2 | 0.15~1.5 | Thread | 6.3 | 12,16,25...42 |

| DN15 | 0.6~6 | 0.4~8 | Thread(Flange) | 6.3,2.5(Flange) | 4.0,6.3,12,16,25...42 |

| DN20 | 0.8~8 | 0.45~9 | Thread(Flange) | 6.3,2.5(Flange) | 4.0,6.3,12,16,25...42 |

| DN25 | 1~10 | 0.5~10 | Thread(Flange) | 6.3,2.5(Flange) | 4.0,6.3,12,16,25...42 |

| DN32 | 1.5~15 | 0.8~15 | Thread(Flange) | 6.3,2.5(Flange) | 4.0,6.3,12,16,25...42 |

| DN40 | 2~20 | 1~20 | Thread(Flange) | 6.3,2.5(Flange) | 4.0,6.3,12,16,25...42 |

| DN50 | 4~40 | 2~40 | Thread(Flange) | 2.5 | 4.0,6.3,12,16,25...42 |

| DN65 | 7~70 | 4~70 | Flange | 2.5 | 4.0,6.3,12,16,25...42 |

| DN80 | 10~100 | 5~100 | Flange | 2.5 | 4.0,6.3,12,16,25...42 |

| DN100 | 20~200 | 10~200 | Flange | 1.6 | 4.0,6.3,12,16,25...42 |

| DN125 | 25~2500 | 13~250 | Flange | 1.6 | 2.5,4.0,6.3,12,16...42 |

| DN150 | 30~300 | 15~300 | Flange | 1.6 | 2.5,4.0,6.3,12,16...42 |

| DN200 | 80~800 | 40~800 | Flange | 1.6 | 2.5,4.0,6.3,12,16...42 |