Thermal gas mass flow meter for nitrogen

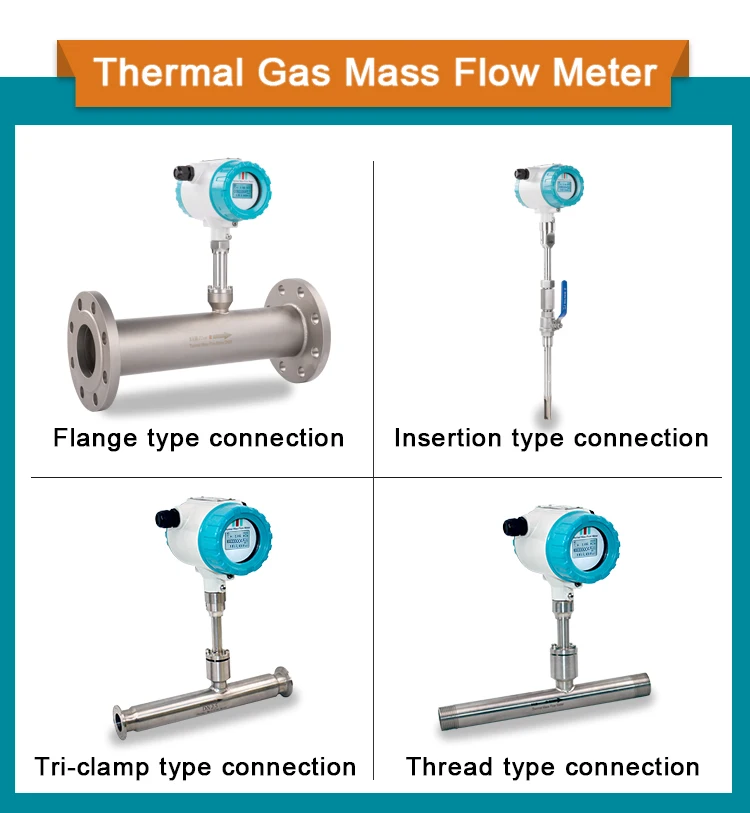

- Connect :Flange,Tri-clamp,Thread,Insert

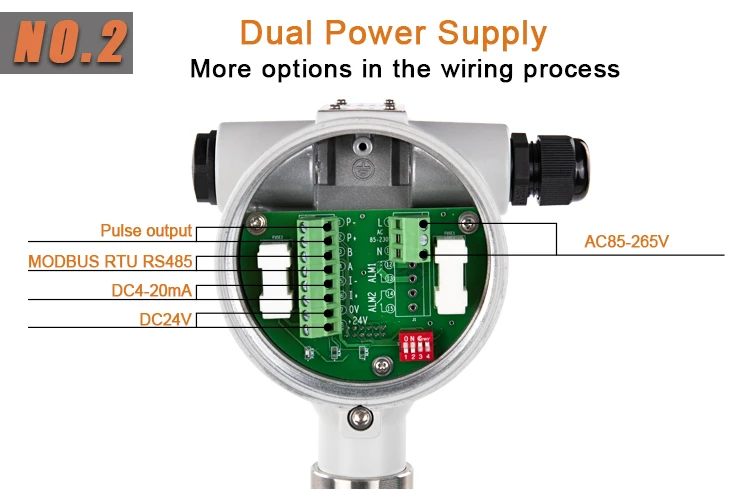

- Output:4-20mA,Pulse,RS485

- Power supply:24VDC or 220VAC

- Accuracy:1.0% for inline type,1.5% for insert type

- Body:Standard:SS304,Option:SS316

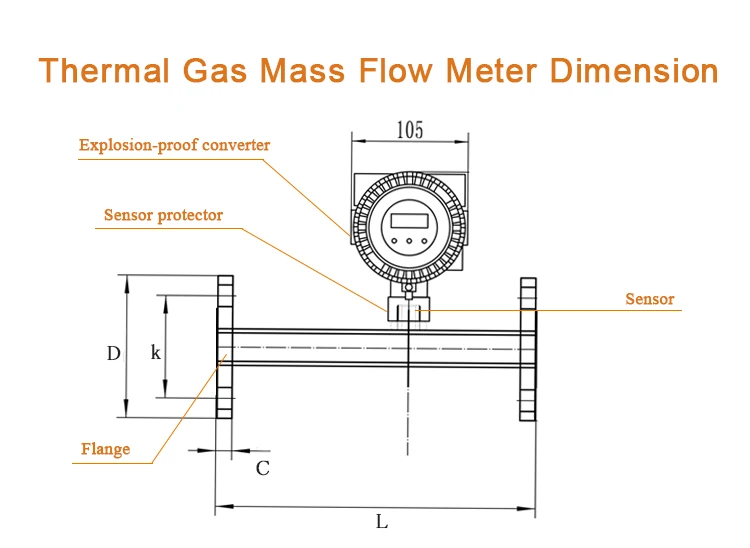

Thermal Gas Mass Flow Meter Installation Parameters

| Nominal dia. | Flange outer dia. | Center hole | Bolt hole | Screw bolt | Flange thickness | Installation length |

| DN | D | k | n x L | C | L | |

| 10 | 90 | 60 | 4x14 | M12 | 14 | 280 |

| 15 | 95 | 65 | 4x14 | M12 | 16 | 280 |

|

20 |

105 | 75 | 4x14 | M12 | 18 | 280 |

| 25 | 115 | 85 | 4x14 | M12 | 18 | 280 |

| 32 | 140 | 100 | 4x18 | M16 | 18 | 350 |

| 40 | 150 | 110 | 4x18 | M16 | 18 | 350 |

| 50 | 165 | 125 | 4x18 | M16 | 20 | 350 |

| 65 | 185 | 145 | 4x18 | M16 | 20 | 400 |

| 80 | 200 | 160 | 8x18 | M16 | 22 | 400 |

| 100 | 220 | 180 | 8x18 | M16 | 22 | 500 |

| 125 | 250 | 210 | 8x18 | M16 | 24 | 500 |

| 150 | 285 | 240 | 8x22 | M20 | 24 | 500 |

| 200 | 340 | 295 | 12x22 | M22 | 26 | 500 |

| 250 | 405 | 355 | 12x26 | M22 | 28 | 500 |

| 300 | 460 | 410 | 12x26 | M22 | 30 | 500 |

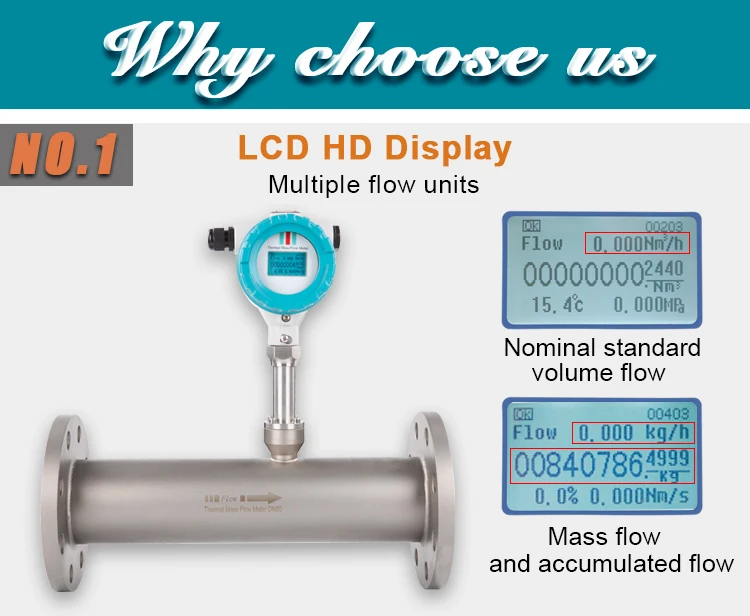

High accuracy, Stable performance, Multiple flow units seanless switching and multi-function setting

With DC4-20mA four-wire output,which is more convenient for remote reception. Support MODBUS RTU RS485 protocol,coordinating the receiving system to collect more data and modify system

Thermal gas mass flow meter is mainly used for measuring gas with low flow and the range ratio could reach 1:1000, which is better than gas flow meter on market and low flow could be measured.

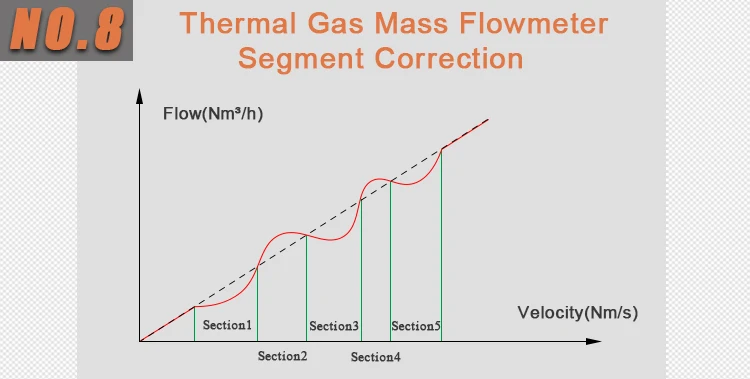

Can be divided into five sections for correcting, this operation will make measuring more precision.

Thermal Gas Mass Flow Meter Parameter

| Media | Various Gases (Except acetylene) |

| Pipe Size |

Insertion type:DN32~DN4000mm Flange type:DN10~DN300 (Can be customized) Tri-clamp type:DN10~DN100 Thread type:DN10~DN100 |

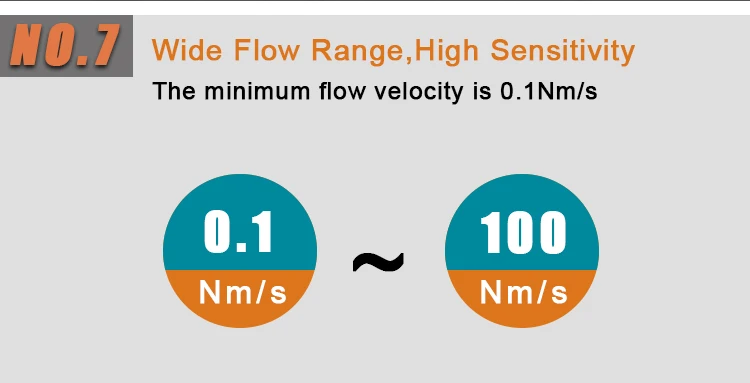

| Velocity | 0.1-100Nm/s |

| Accuracy | In-line type:±1.0% Insertion type:±1.5% |

| Working Temperature | Sensor:-40~+220 degC Transmitter:-20~+80 degC |

| Working Pressure |

Insertion type ≤1.6Mpa Flange type ≤4.0Mpa Special pressure please double check |

| Power Supply |

DC24V and AC220V |

| Response Time | 1s |

| Output | 4-20mA,Pulse,RS485 (HART is optional) |

| Alarm Output | 1-2 way relay,10A/220V/AC or 5A/30V/DC |

| Construction | Compact and Remote |

| Pipe Material | Carbon Steel, Stainless Steel,Plastic etc. |

| Display |

4 lines LCD Mass flowrate, Nominal flowrate, Flow totallizer, Velocity |

| Protection |

IP65 |

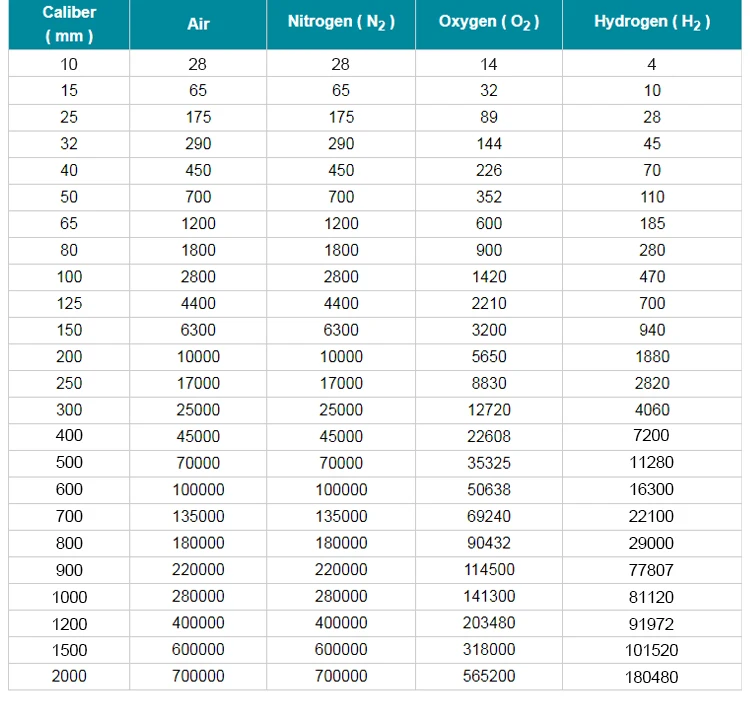

Common Gas Upper Limit Flow

Nominal condition flow is the flow rate at temperature 20℃ and pressure 101.325Kpa.

| Thermal Gas Flow Meter Selection Table | ||||||||

| Model | QTMF | X | X | X | X | X | X | X |

| Caliber | DN10-DN4000 | |||||||

| Structure | Compact | C | ||||||

| Remote | R | |||||||

| Sensor type | Insertion | I | ||||||

| Flange | F | |||||||

| Clamp | C | |||||||

| Thread | S | |||||||

| Material | SS304 | 304 | ||||||

| SS316 | 316 | |||||||

| Pressure | 1.6Mpa | 1.6 | ||||||

| 2.5Mpa | 2.5 | |||||||

| 4.0Mpa | 4.0 | |||||||

| Temperature | -40-220℃ | T1 | ||||||

| Power Supply | AC85~250V | AC | ||||||

| DC24~36V | DC | |||||||

| Signal Output | 4-20mA+Pulse+RS485 | RS | ||||||

| 4-20mA+Pulse+HART | HT | |||||||

Adopt Gas Venturi Sonic Nozzle Calibration Device

Regular inspection and verification guarantee accracy and reliability of the calibration device

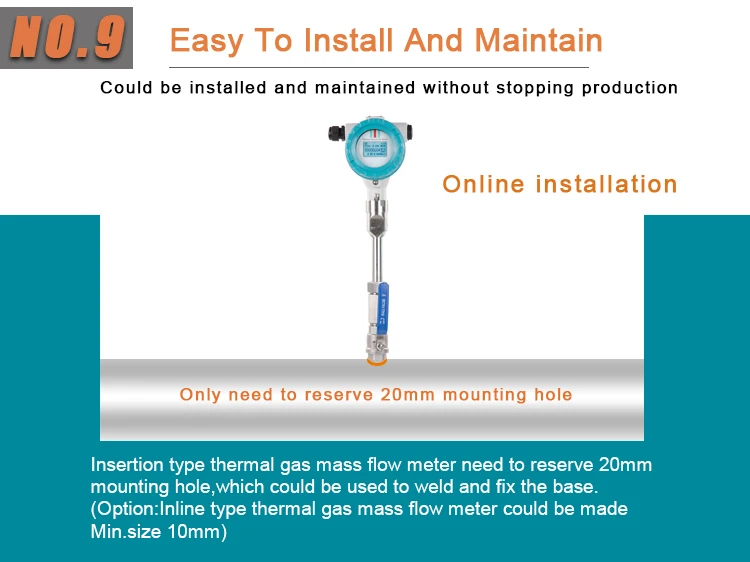

Thermal Mass Flow Meter Installation

Installation location and straight pipe requirements

1. When installing the thermal mass flow meter, keep away from elbows, obstacles, reducers and valves to ensure a stable flow field. It is required to have a long upper straight pipe. The front straight pipe length is greater than 10D, and the rear straight pipe length is greater than 5D.

2. When user site cannot meet the requirements of the straight pipe section, the gas rectifier could be connected in series to greatly reduce the requirements for the straight pipe section.