intelligent precession Vortex flowmeter

- Size:DN20-DN200

- Accuracy:1.5% standard,1% optional

- Medium Temperature:-20~80℃

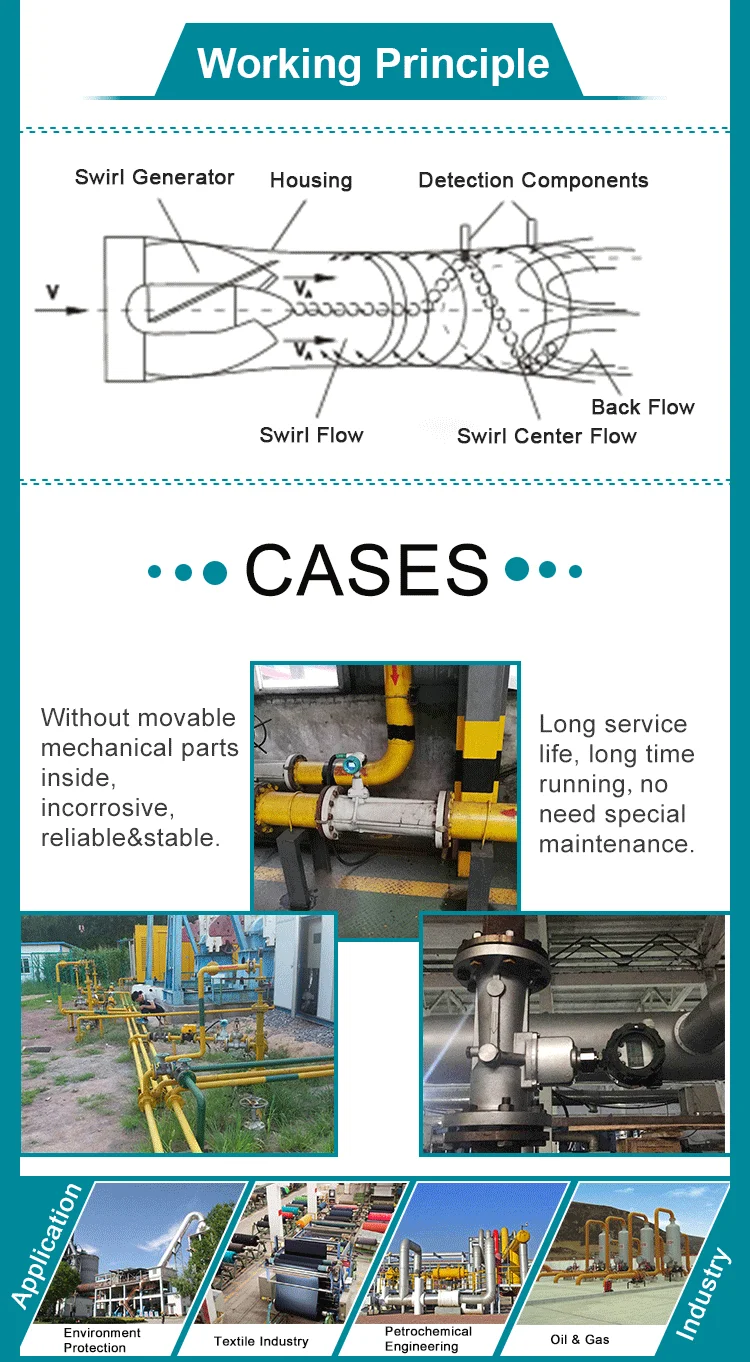

♦ Without movable mechanical parts inside, incorruptible,reliable&stable, long service life, long time runing no need special maintenance.

♦ Adopt 16bits computer chip, high integrity, small size, good performance, powerful functions.

♦ Adopt the advanced intelligent anti-vibration technology, restrain the interference signal caused by vibration and pressure fluctuate.

♦ Adopt EEPROM technology, convenient parameter setting, can save permanently, it can save the one year historal data.

♦ The flow converter could output frequency pulse, 4~20mA analogue signal, and has RS485 interference, it could connect computer network, the transmission distance can reach 1.2km.

♦ Multi physical quantity parameters alarm output, the end user can select any of them.

♦ Flow meter converter could rotate 360degree, easy and convenient installation.

♦ Match with our company FM model data gather, it could carry out the remote data transmission via internet or telephone or internet.

♦ Pressure, temperature signal is flow sensor input method, strong interchangeability.

♦ Lower power consumption, could use the battery powered and connect the external power

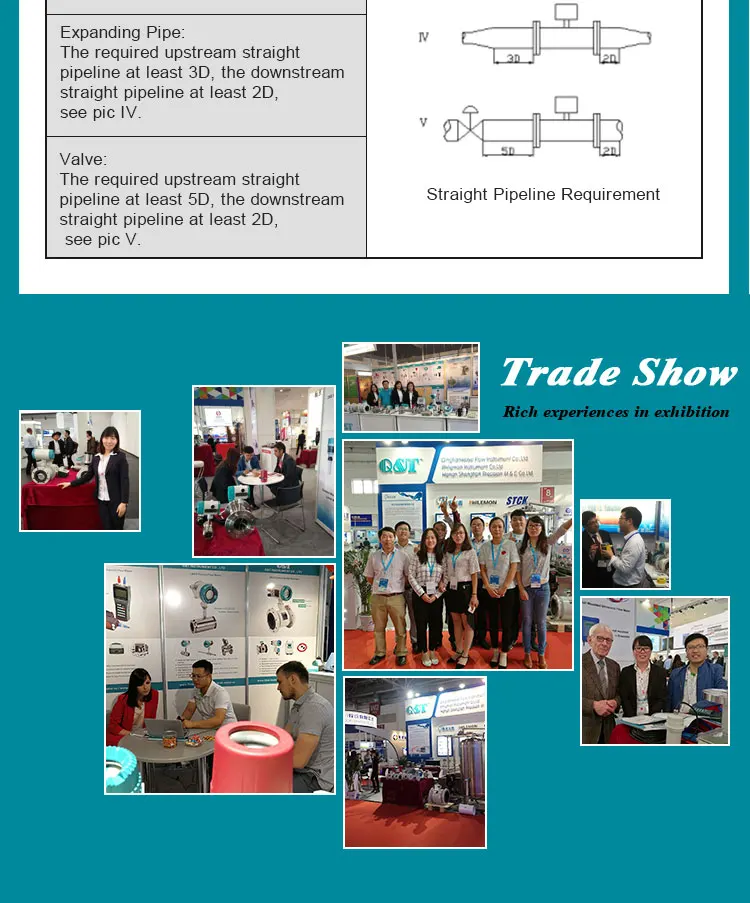

The flow sensor flow profile like the venturi tube shaped wire (pic 2), install one group sprial guide buffle in the side of entrance, while the fluid enter the flow sensor, the guide buffle will press the fluid generate strong swirl flow, when the fluid enter expansion section, the swirl flow will generate second time rotating under the effect of counterflow, and shape the swirl precession phenomenon of gyroscopic shape. The precession frequency in proportion to flow volume, it will not influenced by fluid physical property and density, when get the fluid second time precession, the testing element will get better linearity in the wide flow range. The signal will be magnified via front amplifer, filting and transform into the pulse signal in proportion to flow rate, then send to the micro processor undertake totalizering process with the temperature, pressure testing signal, fianlly it will display the measured result on the LCD displayer ( instantaneous flow total flow and temperature, pressure data).

.jpg)

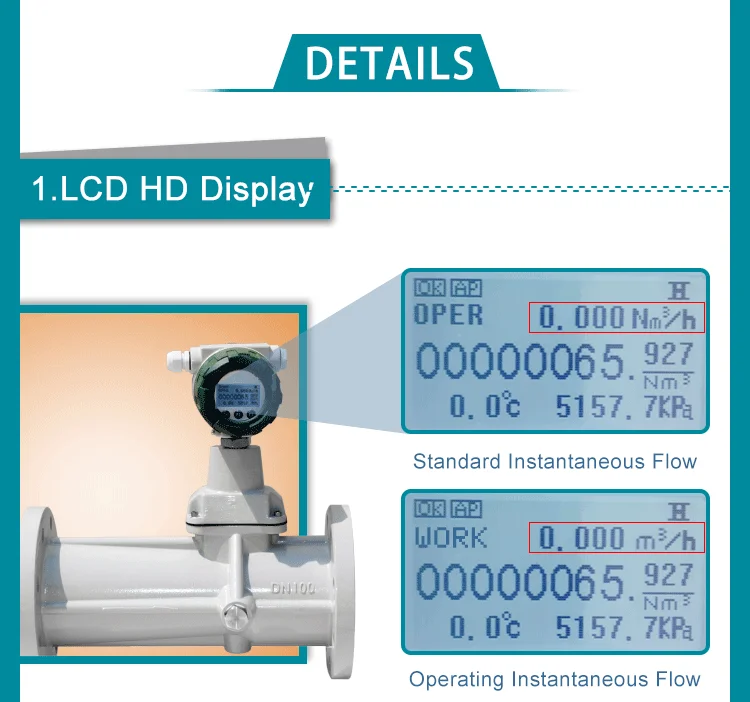

Display parameters can switch freely, can display instantaneous flow (Nm3/h), total flow(Nm3), medium temperature (℃)and pressure (Kpa) at the same screen.

Lower power consumption, could use the battery powered and connect the external power,too.

Double flow sensor, enjoy excellent stability, high accuracy and anti-vibration performance

Can be divided into five sections for correction, this operation will make measuring more accurate

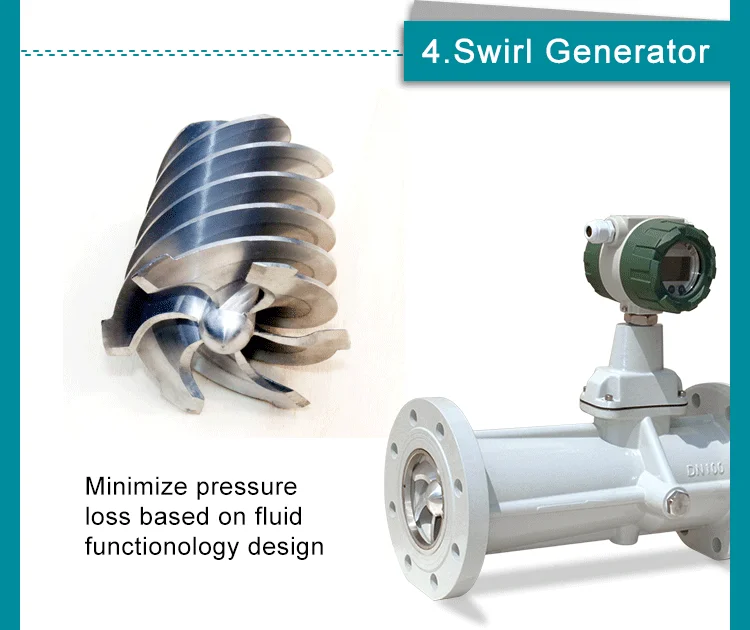

Precession vortex flow meter combines the swirl generator and swirl eliminator in the flow sensor, which can reduce the pressure loss, realize wider flow measuring range, upgrade measurement !

| Precession Vortex Flow Meter Main Technical Parameters | ||||||||

|

Caliber (mm) |

20 | 25 | 32 | 50 | 80 | 100 | 150 | 200 |

|

Flow Range (m3/h) |

1.2~15 | 2.5~30 | 4.5~60 | 10~150 | 28~400 | 50~800 | 150~2250 | 360~3600 |

|

Accuracy |

1.0~1.5% | |||||||

|

Repeatability |

Less than 1/3 of basic error absolute value |

|||||||

|

Working Pressure (MPa) |

1.6Mpa, 2.5Mpa, 4.0Mpa, 6.3Mpa Special pressure please double check |

|||||||

|

Application Condition |

Environment temperature: -30℃~+65℃ Relative humidity: 5%~95% Medium temperature: -20℃~+80℃ Atmospheric pressure: 86KPa~106KPa |

|||||||

|

Working Power |

24VDC+3.6V battery power, can remove the battery | |||||||

| Output Signal | 4-20mA, pulse, RS485, alarm | |||||||

| Applicable Medium | All gases (except steam) | |||||||

| Explosion-proof Mark | Ex ia II C T6 Ga | |||||||

Pressure Loss Curve

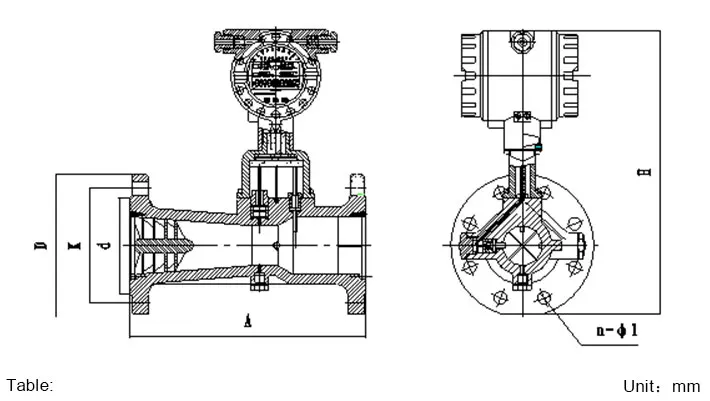

Installation Dimension Drawing

|

Caliber (mm) |

Length (mm) |

PN1.6~4.0MPa |

|||||||||||||||||

| H | Dφ | Kφ | N | L | dφ | H | Dφ | Kφ | N | L | dφ | H | Dφ | Kφ | N | L | dφ | ||

| 25 | 200 | 305 | 115 | 85 | 4 | 14 | 65 | ||||||||||||

| 32 | 200 | 320 | 140 | 100 | 4 | 18 | 76 | ||||||||||||

| 50 | 230 | 330 | 165 | 125 | 4 | 18 | 99 | ||||||||||||

| 80 | 330 | 360 | 200 | 160 | 8 | 18 | 132 | ||||||||||||

| PN1.6MPa | (Special requirements) PN2.5~4.0MPa | ||||||||||||||||||

| 100 | 410 | 376 | 220 | 180 | 8 | 18 | 156 | 390 | 235 | 190 | 8 | 22 | 156 | ||||||

| 150 | 570 | 430 | 285 | 240 | 8 | 22 | 211 | 450 | 300 | 250 | 8 | 26 | 211 | ||||||

| PN1.6MPa | PN2.5MPa |

(Special requirements) PN4.0MPa |

|||||||||||||||||

| 200 | 700 | 470 | 340 | 295 | 12 | 22 | 266 | 490 | 360 | 310 | 12 | 26 | 274 | 510 | 375 | 320 | 12 | 30 | 284 |

Adopt the gas venturi sonic nozzle calibration device and submit the equipment for inspection and verification regularly, which could guarantee the accuracy more stable and reliable !